The Fabtech Trade Fair comes to Orlando

We look forward to meeting you in Florida for the traditional date with Fabtech Expo

October 15, 17 - Booth S34003

Less than a month to go until the Fabtech show in Orlando, where the OCTA Group will be present with a selection of Crippa and SMI products.

We are preparing for the event with a series of innovative solutions designed to fully meet the production needs of US companies.

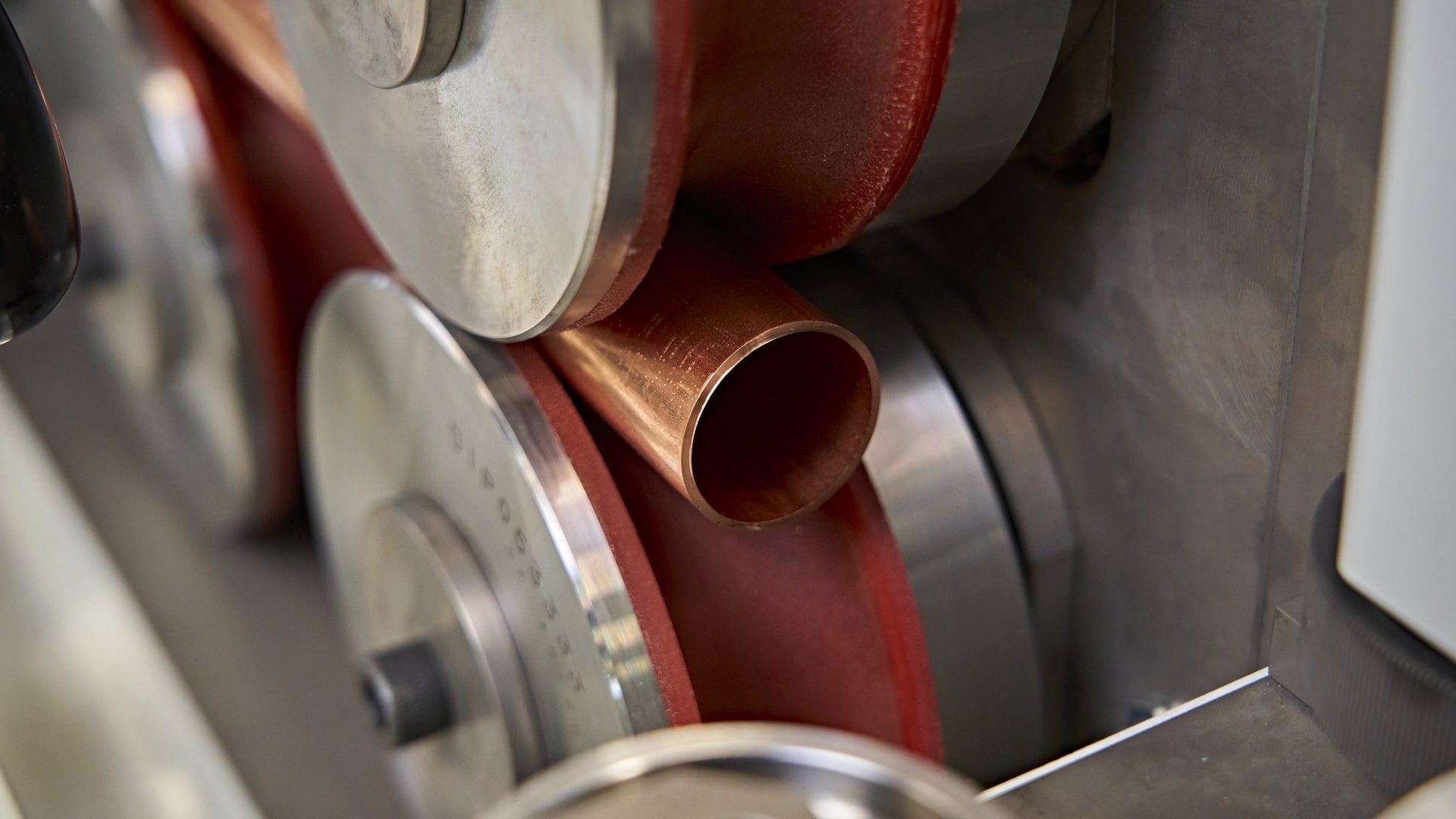

- The 1042E: an Up&Down series CNC tube bender for tubes up to 0,98” in diameter that performs special cross movements of the bending head, which allows it to create tube geometries that normally require post processing operations during the automatic cycle, guaranteeing production speed and precision. Multiradius and multistack, this tube bending machine can simultaneously use more than one tool with different radii and clamping, and the high vertical excursion allows it to integrate the tube loading and unloading phases into the bending head movements. The controlled axes that govern machine movements are driven by absolute digital electric motors with “Full Electric” technology, managed by CNC. The use of this technology guarantees high quality, energy savings, reduced set-up/start up time and scrap minimisation. Three-dimensional UII “User Iso Interface” graphic software on a 19” LCD touch screen, through which the operator can interact intuitively with the machine.

- The 980LE a LINEAR SERIES tube bender that processes tubes up to a diameter of 3”. Compact in size it proves to be extremely versatile, in fact, thanks to its vertical excursion it can simultaneously mount several bending toolsets with different radii and clamping. Moreover, it is designed to be able to be compatible with the pre-existing bending toolings. Moreover, the reliability of the machine is guaranteed by the technological solutions adopted: damage in case of accidental impact of the components is minimized. The "Tangent Boost", i.e. a device that axially pushes the tube during bending even in the slide and counter slide area, enables faster processes with less material waste. A cutting system is also available as an option.

- The SILVER 2CD is an automatic cycle, multi-stack, multi-radius, left and right operated tube bending machine. It can hold up to 7 electric brushless motors which control the advancement, bending, rotation of the processing levels and change in direction, optimising the precision of the movements and reducing energy consumption. The separation of the bent piece from the material coming from the coil is done without producing chips at the orbital incision where the piece is detached, using a false bend. A second blade cutting device can be integrated when required by the properties of the piece being produced or by request. Available options include a device for quick roller changes, drilling machine, laser marking unit, fixed or folding support tables, in-line shaping unit, and many others that make SILVER even more modular and customisable.

All OCTA Group machines feature "Full Electric" technology and can be integrated inside workcells.

In addition to the products on display, our U.S. staff from our new headquarters in Wixom (MI) will be on hand to show you all the solutions in our catalog and help you find the one best suited to your specific production needs.

Don't miss the opportunity to take a closer look at our machines and discover all the technology, software, services and customised solutions that the OCTA Group companies can provide to increase your company's productivity and return on your investment.