Complementary machines

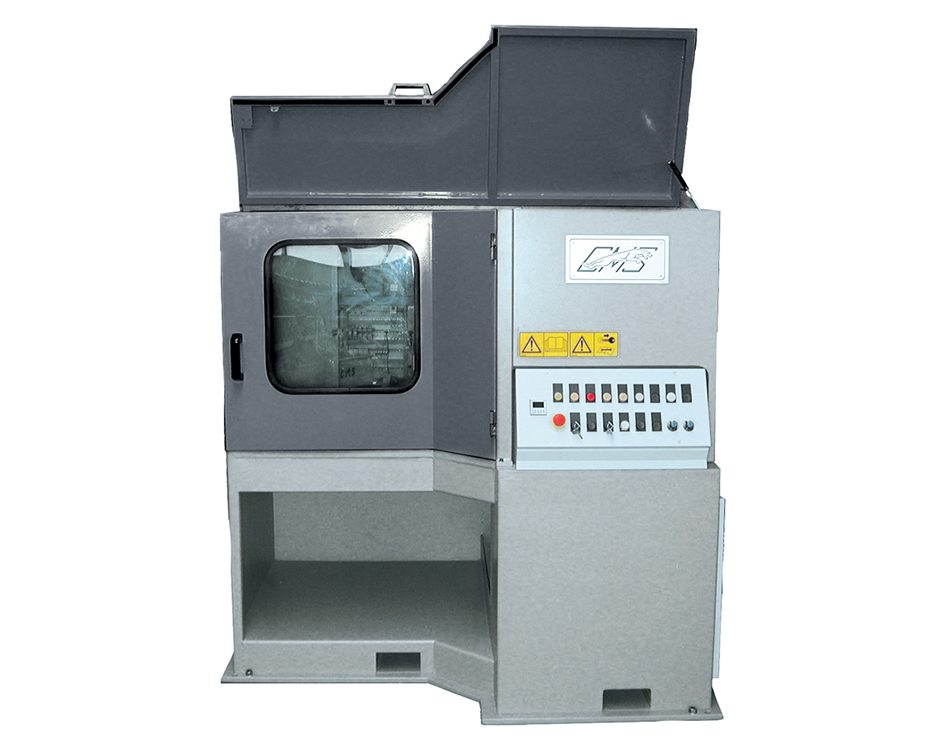

In our strategy of being a global supplier for manufacturers of heat exchangers, we can provide all the complementary machines necessary to produce the components to complete the heat exchange coils. The complementary machines integrate the others to supply complete industrial plants. For the production of finned exchangers C.M.S. designs and builds: - machines for the production or completion of tube sections in the form of elbows or bends, as the crossover machine, the elbow bending and cutting machine, the return bending machine and the ring-assembler; - machines used for the processing of headers or manifolds, such as the manifold drilling machine or the manifold closing machine. Thanks to the flexibility of operation, each machine can be provided with dedicated equipment for each tube diameter, geometry, thickness and material. When producing large quantities of heat exchangers having the same length, the brazing process of the bends can be automated through the use of automatic gas brazing machines. For particular uses, with the coil bending machines it is possible to bend the heat exchanger coils either continuously or by bends with predefined angle and radius.

Can't find what you need?

Don't hesitate to contact us; our technicians are ready to find the solution that best suits your needs.