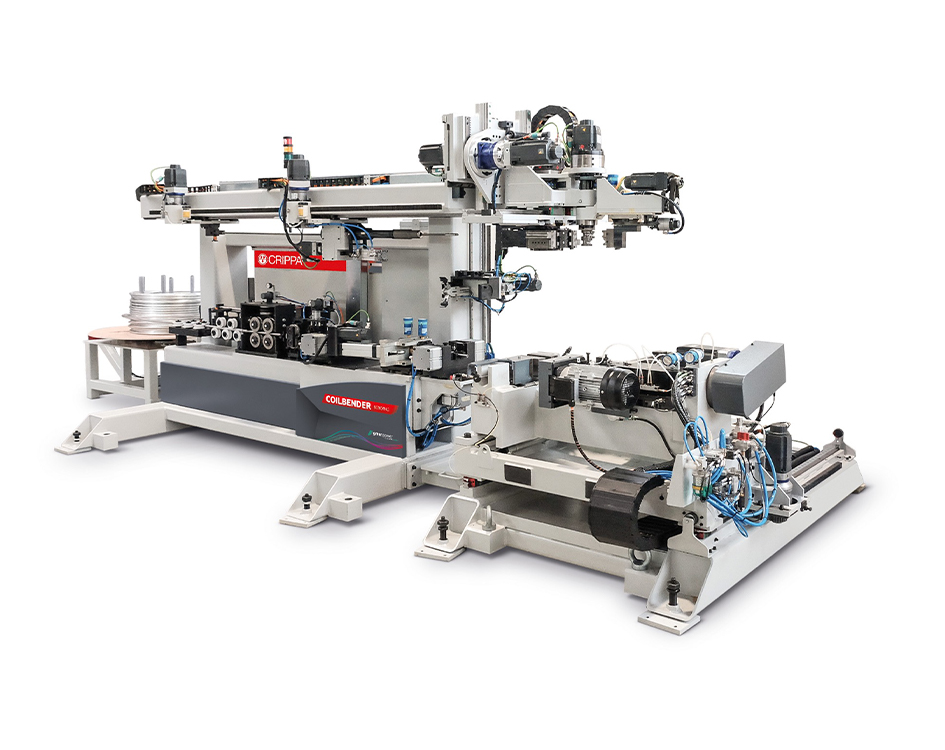

Coilbender

CNC tube bending machine with full automatic cycle.

A new interpretation of the coil bending process: a quick, efficient and compact solution for bending a tube with the mandrel, starting directly from the coil. COILBENDER integrates these features into one system:

- a motorized reel with tube tension control;

- a horizontal and vertical straightening system with roller drive of the tube directly from the reel an orbital cutting system with a wheel and pneumatic tear;

- a latest generation “Full Electric” reverse tube bending machine, right and left bends in cycle with mandrel up to 25mm in diameter and relative numerical control loading system;

- an electric endforming machine with 5Ton deforming power and 2 CNC axes and sideways collapsing movement;

- an integrated unloading system for the processed tube;

- an effective, compact integrated unloading solution.

The machine is driven by a single CNC Siemens 840D sl accessible from a single console. The simplified UII interface software installed on the machine allows for simulation and optimization of bending programs. This machine is designed to be integrated into “Smart Factory” production systems.

Fields of application:

| Bending direction | ← → | Right and left |

| Max Dia. Tube (R=350/450N/mm2) | mm | 25x2 |

| Nr. of CNC axes | 12 | |

| Max bending radius | mm | 120 |

| Max length of tube | mm | 800 |

| Max bending speed | °/sec | 354 |

| Bending resolution | mm | +/-0,05 |

| Max speed of Y axis | m/min | 120 |

| Res of Y axis | Mm | +/-0,05 |

| Tube advancement speed | m/min | 100 |

| Deformation force | Ton | 5 |

| Max deformation length | mm | 150 |

| Clamp force | ton | 7,5 |

| Clamp length | mm | 42 |

| Tool change step | mm | 80 |

| Tool change speed | mm/min | 45000 |

| Tension | V | 400 |

| Voltage | Hz | 50 |

| Power | kW | 20 |

| Weight | Kg | 5000 |