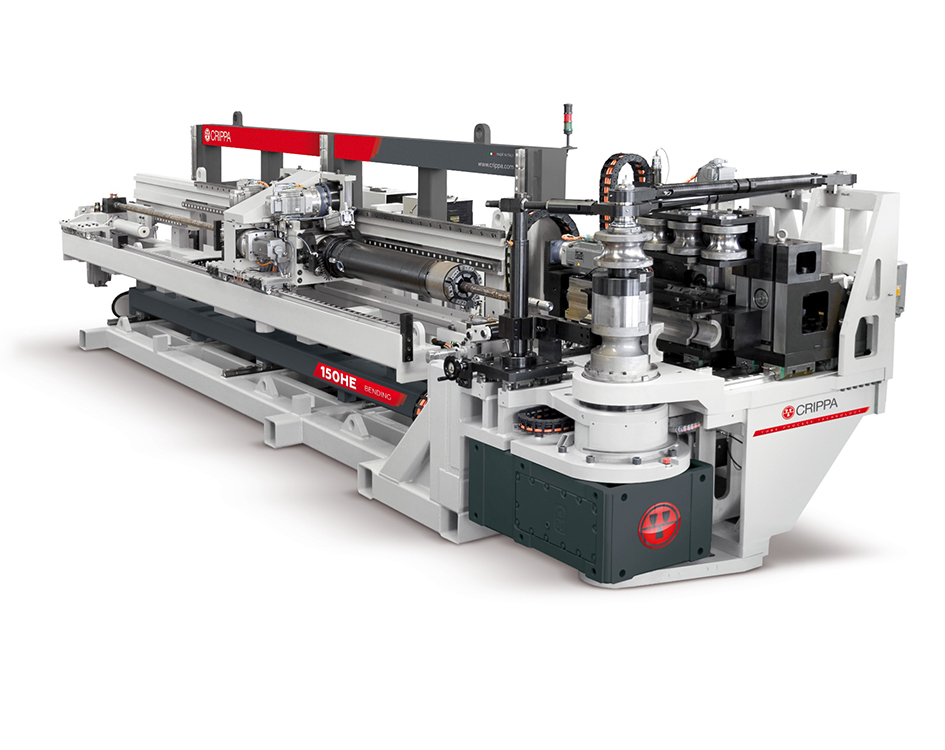

150HE

CNC tube bending machine with full automatic cycle.

The 150HE is the largest machine in the Heavy series, and it can bend mild steel tubes up to 150mm in diameter. Like other machines in the Heavy series, it is known for rigidity and precision, which ensure that it has a superior level of performance than other tube bending machines of a similar size. The bending head structure fixed to the base guarantees the machine has the highest level of rigidity during heavy processes, while the horizontal and vertical movements are left to the tube. In this case also, the vertical axes has a high excursion that allows it to increase the number of available work levels or to interface with existing tools. The compact bending head allows the machine to create particularly complex tube geometries during the cycle, when normally operations like these require double bending directions. The nine axes are driven by absolute digital motors with Full Electric technology controlled by a CNC Siemens 840D sl The use of Full Electric technology, combined with dual axes, guarantees high efficiency, quality, energy savings, reduced set-up/start up time and scrap minimisation. With the “Tangent Boost” device, the machine can push axially on the tube during bending, also in the slide/wiper-die area, optimising tube development and reducing scrap even more. One of the available options is a CNC double blade cutting system. The high production rate, ability to produce bends with CLR/DIA ratio even lower than 0.8 or thrust bends with variable radius make this machine particularly suitable for use in sectors where intensive processes with high levels of precision are required. The machine has three-dimensional graphics software on a 19” LCD Touch screen from which the operator can interact intuitively with the machine. The UII (User Iso Interface) also allows the operator to simulate and optimise bending programs. This machine is designed to be integrated into Smart Factory systems.

The machine is also available in a single stack version.

Fields of application:

| Bending direction | ←o→ | Right or left |

| Mild steel max tube Dia. (R=350/450N/mm2) | mm | 150x3 |

| Inox steel max tube Dia. | mm | 150x2,2 |

| Nr CNC axes | 11 | |

| Max bending radius | mm | 450 |

| Useful length of standard tube inside the collet/hitch feeding | mm | 4200/7500 |

| Max OD for hitch feeding | mm | 130 |

| Max bending speed | °/sec | 50 |

| Res of Y axis | mm | +/-0,05 |

| Tension | V | 400 |

| Mains frequency | Hz | 50 |

| Power | kW | 60 |

| Weight | Kg | 24000 |

| Height between bending planes | mm | 525 / 740 |